During interior decoration, waterproofing and leak-sealing materials are essential in many areas—all for the sake of convenience and practicality in renovation projects. There is a wide variety of materials available on the market for waterproofing and sealing leaks. But how much do you know about the ingredients of leak-sealing sprays? Let’s take a closer look!

Waterproof Leak-Sealing Materials

Polymer-Modified Cement

This is a type of waterproof material with excellent flexibility. It is primarily produced using polymers as the base material through multiple processes. This material also demonstrates strong water resistance, high temperature tolerance, and long-term durability, making it a reliable choice.

Permeability-Resistant Grout

This material is processed from a variety of raw ingredients. Although the production process is relatively complex, its performance is outstanding. It offers effective thermal insulation, is non-toxic and harmless, and has a wide range of applications. It also possesses strong oxidation resistance, high strength, and excellent waterproofing effects.

Asphalt Waterproof Material

Asphalt waterproof material is highly practical and delivers reliable results after application. Through multiple construction steps, this material exhibits good flexibility, high temperature resistance, and pressure resistance, making it an excellent option for waterproofing and leak-sealing.

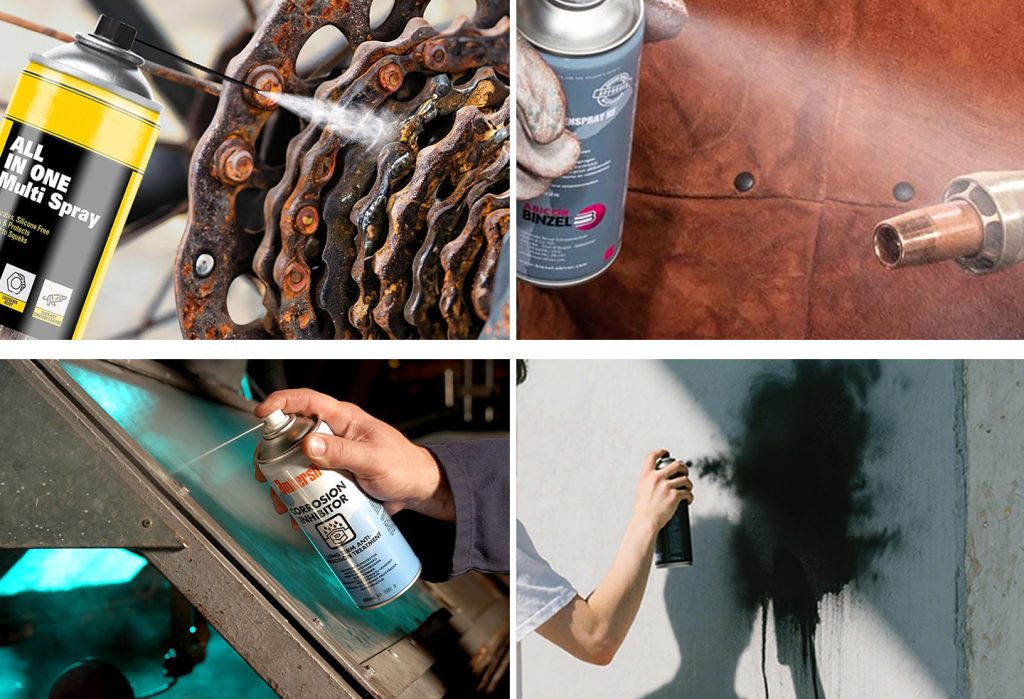

Nowadays, there are many self-spray waterproof leak-sealing products on the market. These ready-to-use sprays are convenient, offer strong coverage, and deliver a fine mist, making them highly popular among users. Below, we introduce the equipment used to fill these products for your reference.

Self-spray waterproof leak-sealing products consist of an aerosol can, a valve, propellant gas, the liquid compound, a nozzle, and a cap. During production, aerosol filling machines are used to complete the filling, sealing, and charging processes.

Depending on production volume and level of automation, filling equipment for self-spray waterproof leak-sealing products can be classified into semi-automatic aerosol filling machines and fully automatic aerosol filling lines, catering to the diverse needs of different customers.

Semi-automatic equipment includes liquid filling, valve placement, sealing, and gas charging. It uses pneumatic cylinders to move containers instead of manual pushing, offering both manual and automatic operation modes for flexibility and efficiency. It comes with an automatic valve positioning device for better sealing quality. Each filling head can be controlled individually to prevent leakage when no can is present. The sealing head uses a guided sealing method for high-quality results, and the gas charging head employs guided charging for accuracy, efficiency, and reduced gas consumption. All processes are integrated into a single workstation, which saves space and reduces labor requirements.

Fully automatic equipment is developed based on semi-automatic systems. It integrates all processes—including container sorting, liquid filling, valve installation, valve positioning, sealing, gas charging, weighing, nozzle attachment, and cap placement—replacing manual operations with mechanical ones. With a high degree of automation, it meets the demands of large-scale production, with a daily output exceeding ten thousand units.