1. Why This Cleaner Brand Switched to Tinplate Aerosols?

Mr. Li, a procurement manager at a household cleaner company, recently made a key decision: shifting 30% of aluminum can orders to custom tinplate cans. “The EU’s new regulation requires over 80% recyclability by 2026. Tinplate’s 90% recycling rate meets the standard perfectly, plus its production energy consumption is 35% lower than aluminum—saving nearly 150,000 RMB annually.” This choice reflects the upgraded material adaptability of tinplate aerosol production lines.

2. Packaging Material Adaptability: Tinplate as the Eco-Favorite (2025 Data)

| Material Type | Key Features | Application Scenarios | EU 2025 Regulation Compliance |

|---|---|---|---|

| Tinplate Can | 100% recyclable (<2% loss after 10 cycles), low cost, high barrier | Household cleaners, insecticides, industrial aerosols | Grade A recyclability (95%), total heavy metals (Pb/Cd/Hg/Cr⁶⁺) <100mg/kg |

| Aluminum Can | Lightweight, good formability | Premium cosmetics, medical sprays | 75% recycling rate, 40% higher carbon emission than tinplate |

| Plastic Can | Impact-resistant, flexible design | Low-pressure spray products | 55% recycling rate required by 2026, not for corrosive materials |

Tinplate Tech Breakthrough: A new eco-coating with 7-8% quantum dots enables tinplate to adapt to acidic water-based materials, solving traditional corrosion issues.

3. Filling Material Adaptation List (Adjustable Line Parameters)

- Liquid Materials

- Suitable for: Alkaline cleaners, essential oils, moisturizing sprays

- Line adjustment: Filling speed reduced to 300 cans/min, vacuum defoaming device installed

- Mixed Materials

- Suitable for: Exfoliating mousse with particles, insecticide emulsions

- Line adjustment: Stirring filling heads adopted, sealing pressure increased to 0.3MPa

- Special-requirement Materials

- Suitable for: Food-grade release agents (food contact certification needed)

- Key configuration: FDA-compliant inner coating

4. Debunking Tinplate Myths

Q1: Is tinplate more prone to rust than aluminum?

A: No! The 2025 quantum dot coating enables tinplate to resist salt spray for 720 hours—far exceeding the 200 hours of traditional coatings, even for bathroom sprays.

Q2: Is tinplate recycling unprofitable?

A: Recycling 1 million tinplate cans saves 2.5 tons of steel. Europe’s recycling rate hits 90%, with 3x higher profit than plastic recycling.

5. Production Line Adaptation Tips

- Material Switching: Replace with tinplate-specific stamping molds, adjust sealing temperature to 180℃

- Eco-upgrade: Install VOC recovery systems to meet EU PFAS restrictions

- Smart Inspection: 3D vision systems for 100% coating uniformity detection

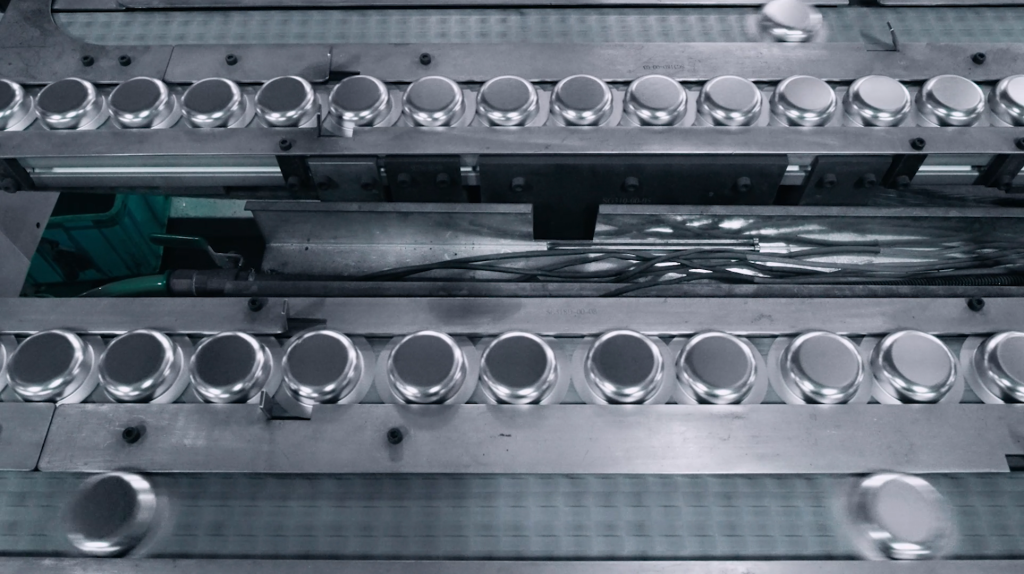

With the EU’s “Packaging and Packaging Waste Regulation” taking effect in 2026, tinplate aerosols are becoming the top choice for global enterprises due to high recyclability and cost advantages. Production lines can switch from aluminum to tinplate in 48 hours, helping businesses seize the eco-friendly market opportunity.