As global environmental policies tighten and enterprises’ demand for sustainable development grows, tinplate aerosol cans — which combine “high recyclability” and “strong adaptability” — are rapidly expanding from traditional fields such as automotive care and industrial manufacturing to scenarios like home care and architectural decoration. According to the 2024 Global Aerosol Can Market Report, annual sales of tinplate-based aerosol cans increased by 12.3% year-on-year, with customized products accounting for over 40% of the total — becoming a core driver of market growth.

From Workshops to Homes: The “Multi-Scenario Adaptability” of Tinplate Aerosol Cans

In the automotive aftermarket, tinplate aerosol cans have long been a “standard tool.” The after-sales director of an automotive 4S store stated: “Products like carburetor cleaners and dashboard waxes packaged in tinplate cans can maintain a shelf life of over 2 years, and the atomization effect from pressing the nozzle is stable. Customer repurchase rates are 15% higher than those for plastic bottle packaging.” Behind this lies the high barrier property of tinplate — it effectively isolates volatile components from air contact. Meanwhile, its 100% recyclable nature aligns with automakers’ transition toward “green after-sales services.”

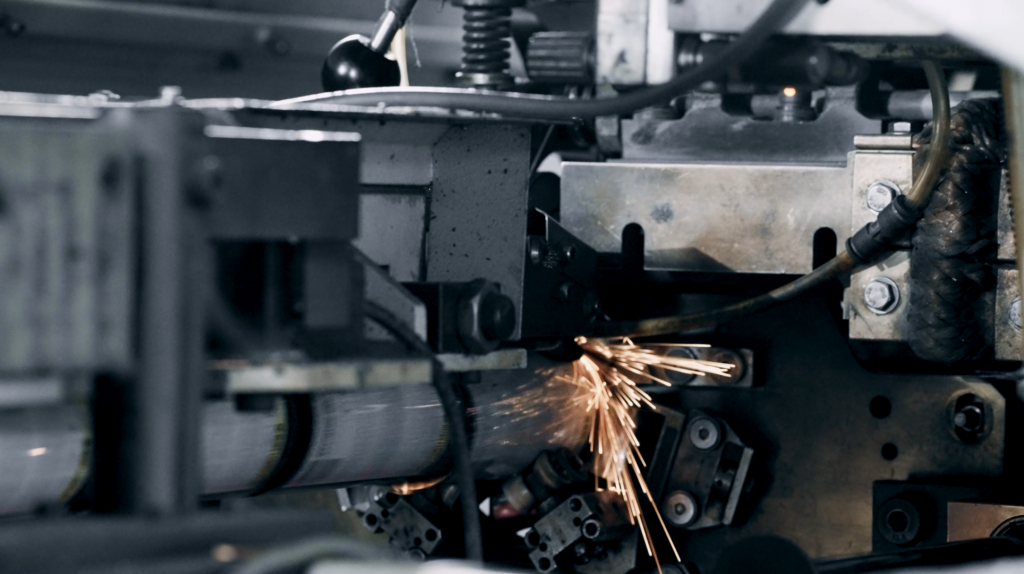

Beyond the automotive sector, tinplate aerosol cans are solving “customization pain points” in industrial workshops. The procurement manager of a machinery manufacturing enterprise noted: “We needed 500ml rust remover aerosol cans with a 65mm diameter. After contacting multiple suppliers, only SAILON could complete sampling within 7 days, and the can’s anti-corrosion coating meets the high-temperature requirements of our workshop.” This flexible customization capability stems from the advantages of three-piece tinplate aerosol cans — they can be adjusted to diameters of 45–70mm and capacities of 200–1000ml on demand. The cost of filling equipment is 30% lower than that of two-piece aluminum cans, making them particularly suitable for industrial needs involving small-batch, multi-specification products.

In home and construction scenarios, the “environmental attributes” of tinplate aerosol cans are even more favored. After the implementation of the 2025 National Standard Limits of Harmful Substances in Civil Building Decoration Materials, tinplate aerosol cans using chromium-free passivation technology — which reduce VOC emissions by 90% — have become the preferred packaging for products such as air fresheners and door/window foam adhesives. Data shows that in 2024, the usage of tinplate aerosol cans in the construction sector increased by 22% year-on-year, while the home care sector saw a growth rate of 18.5%.

27 Years of Technological Expertise: Customization + Environmental Protection Solve Industry Pain Points

“Early customers only cared about ‘whether it can hold the product’; now they care more about ‘whether it can hold it environmentally and in line with brand needs,’” said the technical director of SAILON in an interview. As an enterprise with 27 years of R&D and manufacturing experience in tinplate aerosol cans, it has developed three core competencies:

- Full-range Customization Coverage: Capable of producing aerosol cans with diameters of 45/52/57/60/65/70mm, adapting to scenarios such as automotive care (small-capacity sprays), industrial manufacturing (large-capacity rust removers), and architectural decoration (extra-large-capacity foam adhesives), with a minimum sampling cycle of only 7 days.

- Environmental Technology Upgrades: Adopts food-grade inner coatings and chromium-free passivation processes. Products comply with the EU PPWR Packaging Regulation and China’s GB/T 38053-2024 environmental standard, reducing carbon emissions by 2.5 tons per 10,000 tinplate cans compared to traditional processes.

- End-to-end Quality Control: From the procurement of tinplate raw materials (using first-grade substrates from Baosteel, Angang, etc.) to can stamping and seal testing, 12 quality inspection procedures are implemented to ensure a leakage rate of less than 0.01% — far below the industry average of 0.05%.

Future Trends: Tinplate Aerosol Cans to Become More “Intelligent” and “Lightweight”

Regarding the industry’s future, the aforementioned technical director predicted: “With the penetration of IoT technology, tinplate aerosol cans may incorporate NFC chips to enable ‘anti-counterfeiting traceability + usage reminders.’ At the same time, through material and process optimization, the can thickness is expected to be reduced from the current 0.23mm to 0.18mm, further lowering costs and energy consumption.”

Currently, SAILON (Replaceable with Company Name) has launched the “Lightweight Tinplate Aerosol Can” R&D project, with sample release expected in the first half of 2026. For enterprises with customization needs, it offers one-stop services including “specification design + exterior printing + performance testing,” helping clients seize opportunities in the environmental transformation.