When you pop open a can of beans or sip a refreshing drink from a metal container, have you ever wondered about the material that makes it all possible? Meet tinplate—the unsung hero of the packaging world. But what exactly is it, and why does it matter? Let’s dive in.

What Is Tinplate?

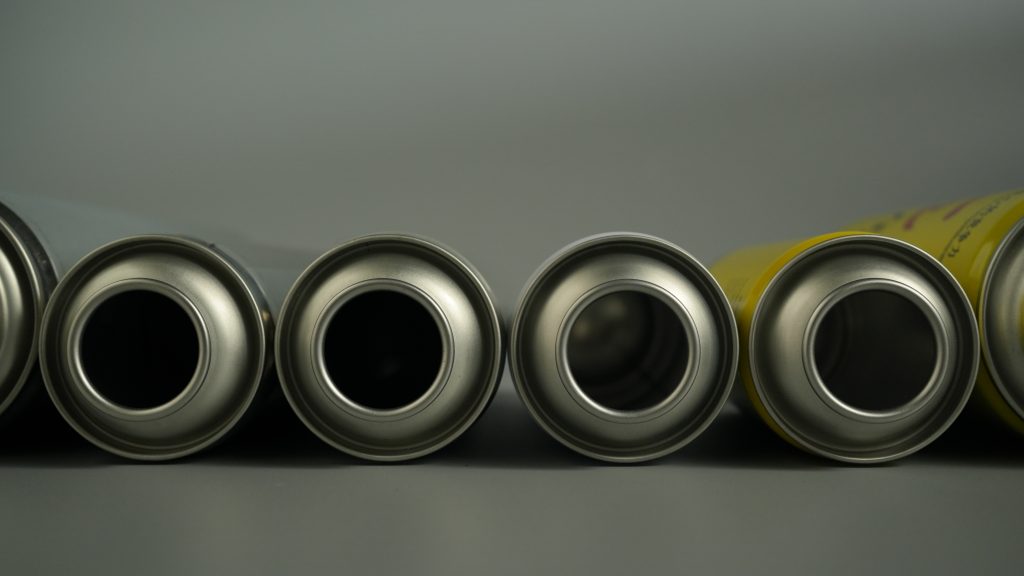

Tinplate, known scientifically as electrolytic tin-coated sheet steel (SPTE), is a cold-rolled low-carbon steel sheet or strip coated on both sides with commercial pure tin. This unique combination offers the strength and formability of steel alongside the corrosion resistance, solderability, and aesthetic appeal of tin. It’s non-toxic, highly durable, and incredibly versatile—used widely in packaging for food, beverages, oils, chemicals, paints, spray cans, caps, and countless daily essentials.

And What About TFS?

Ever heard of TFS? It stands for Tin-Free Steel, or chromium-electroplated steel. Born out of the need to reduce reliance on expensive tin, TFS offers cost efficiency and superior paint adhesion. However, it falls short in corrosion resistance and visual charm compared to tinplate. Plus, it can’t be soldered—instead, it requires resistance welding or adhesive bonding. Commonly used for crown caps and mildly acidic canned foods, TFS is gaining traction but remains a newcomer without an official national standard in China. Most producers refer to ISO 11950:1995 or Japanese industrial standards.

A Quick Trip Through History

The story of tinplate began in 1800 when the British introduced the first tin can for food preservation—crafted using the hot-dip tinning method. The 1820s saw rapid growth in the U.S., fueled by rising demand. In 1847, automated can-making machines replaced manual labor, boosting production. The invention of electric welding in 1900 further revolutionized the industry. By the 1990s, high-speed welding allowed outputs of up to 1,000 cans per minute! And from the mid-20th century, electro-chromium coated steel emerged as a partial alternative to traditional tinplate.

Classified by temper level, plating volume, steel type, annealing method, and surface finish, tinplate boasts excellent solderability, weldability, formability, and appearance. You’ll find it in food cans, beverage containers, 18L drums, art cans, aerosol cans, bottle caps, home appliances, electrical parts, oil filters, and cable sheathing.

Did you know? Canned food consumption per capita (excluding beverages) is 90kg in the U.S., 43kg in the EU, 25kg in Japan, and 8kg globally. But in China, it’s only 1.8kg! Producing high-quality canned goods requires three pillars: excellent raw materials, advanced processing techniques, and superior packaging—which is where tinplate shines.

Why Tinplate Is a High-Precision Product

Tinplate isn’t just any steel—it’s the pinnacle of cold-rolled production. Here’s why:

- The base iron is ultra-pure low-carbon soft steel (C<0.12%). Strict controls are placed on residual elements like P, S, Si, Cu, Cr, and Mn. Some batches even require vacuum degassing to remove impurities.

- During hot rolling, temperature gradients must be meticulously managed to prevent segregation.

- Cold rolling reduces a 2mm hot-rolled strip (over a meter wide) to about 0.20mm at speeds up to 30 meters per second. Over 24 hours of operation, thickness deviation must not exceed 5 micrometers. Imagine the precision—a machine with the power of a hydraulic press and the accuracy of a Swiss watch!

- Annealing temperature and speed directly affect hardness.

- Finally, variations in cleaning, electroplating, melting, passivation, or oiling can drastically impact quality.

In short, tinplate is a high-tech product demanding extreme precision and mirror-like surface finish.

Key Quality Metrics

Over 40 tests are conducted during production and before shipment. However, most international standards (except the U.S.) focus on formability parameters like flatness, angular accuracy, and thickness tolerance—not intrinsic corrosion resistance.

The five famous internal quality indicators are:

- Tin coating thickness: Thicker is better, but costlier.

- Tin-iron alloy layer (measured by ATC and thickness): Denser is better.

- Iron dissolution value (ISV): Lower values mean fewer pores in the tin layer.

- Steel surface cleanliness (PLA): Lower is better.

- Tin crystal size: Larger crystals observed under microscopy are desirable.

Additional factors influencing corrosion resistance include chromium content in the passivation film, oxide layer thickness, and oil coating weight.

How Developed Nations View and Manage Tinplate

Why don’t advanced economies export their best tinplate? Three reasons:

- Poor-quality tinplate can lead to excess tin/iron ions leaching into food, compromising safety and taste—sometimes ruining entire batches.

- It’s a high-technology product.

- Tin is a scarce strategic resource. Developed countries guard it closely and import rather than export.

The U.S. Department of Defense oversees tinplate standards—the only country with mandatory limits on all five internal quality metrics. Their top-grade “K-grade” tinplate is banned from export; only lower “waste-grade” is available internationally. Russia produces limited quantities (around 600k tons yearly) of lower-quality tinplate.

Meanwhile, European and Japanese suppliers often sell mid- or lower-grade products to developing markets—technically meeting international standards like ISO 11949:1995 but lacking premium performance. Beware: the Japanese standard JIL G3303-87 is particularly lenient, allowing thickness variations up to ±10%. So, if you order 0.22mm tinplate, you might receive anywhere between 0.198–0.242mm! Always specify stricter parameters in contracts.

Fun Q&A

- Q: Why are some cans shinier than others?

A: It’s all about the tin coating quality and surface treatment—premium grades have mirror-like finishes! - Q: Can tinplate rust?

A: Thanks to the tin layer, it’s highly corrosion-resistant. But poor quality or damaged coating can lead to rust. - Q: Why do some cans have a longer shelf life?

A: Better tinplate means fewer micro-pores, less interaction with contents, and longer preservation.

Think twice when choosing packaging materials—because behind every great can is even greater tinplate!