Ever thought about how that deodorant, air freshener, or paint sprays out so perfectly? It’s all thanks to the aerosol can, an engineering marvel designed for convenience. These cans deliver a controlled mist or spray across a wide range of industries, from personal care to household and industrial products. But behind that simple “pssst” sound is a world of rigorous testing and precise material science that ensures safety, performance, and reliability. At the core of this world is tinplate. Let’s explore.

The Unsung Hero: What Exactly is a Tinplate Aerosol Can?

“What is tinplate?” is a question many people ask. It’s not a term we use every day. In simple terms, tinplate is a sturdy steel material with a thin, protective tin coating. This coating is applied through electrolytic tinning, resulting in “tin-coated steel,” or tinplate. The tin layer acts like a superhero cape for the iron base, making it highly resistant to rust and corrosion, which is crucial for protecting the contents inside the can.

But why is this so important for aerosols? The answer lies in pressure.

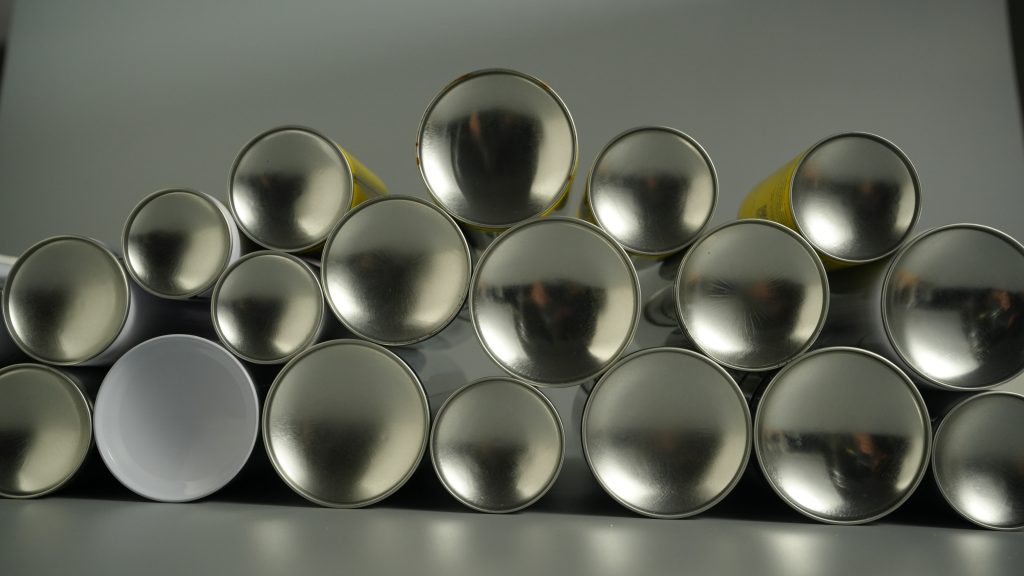

The Power Within: Why Aerosol Cans Need to Be Tough

An aerosol can contains a high-pressure environment. A propellant gas is compressed inside, creating pressure much higher than the outside atmosphere. When you press the actuator, this pressure forces the product through the valve, creating a fine, consistent spray—a cloud of tiny particles. It’s like having a mini fire extinguisher for everyday use!

This internal pressure means the can itself must be extremely strong. A weak container could deform, leak, or even rupture in the worst-case scenarios. That’s why choosing the right material is a matter of safety and performance. While there are several strong metals, one stands out as the perfect balance of strength, cost, and functionality.

The Showdown: Tinplate vs. The Competition (Spoiler: Tinplate Wins)

You might wonder, “Why not use stainless steel? It’s strong and doesn’t rust!” That’s a valid point. Let’s compare the two:

| Feature | Stainless Steel Can | Tinplate Can |

|---|---|---|

| Strength & Rigidity | Excellent | Excellent |

| Corrosion Resistance | Excellent | Excellent (thanks to tin coating) |

| Formability | Good | Superior. Highly malleable for complex shapes. |

| Cost | High | Most cost-effective in the metal packaging industry |

| Opacity | Opaque | Opaque (protects light-sensitive contents) |

| Sustainability | Recyclable | Highly recyclable and eco-friendly |

As you can see, while stainless steel is a great material, it comes with a much higher price tag. Tinplate matches it in key areas like strength and corrosion resistance but outperforms it in formability and, most importantly, cost-effectiveness. Iron is inherently cheaper than stainless steel or aluminum. This cost advantage allows manufacturers to provide high-quality, reliable packaging without passing on exorbitant prices to consumers.

Think about the price difference between a stainless steel tea caddy and a tinplate one. The contrast is clear! This economic efficiency is a major reason why tinplate dominates the aerosol can market.

Beyond the Basics: The Superpowers of Tinplate

Shape-Shifter

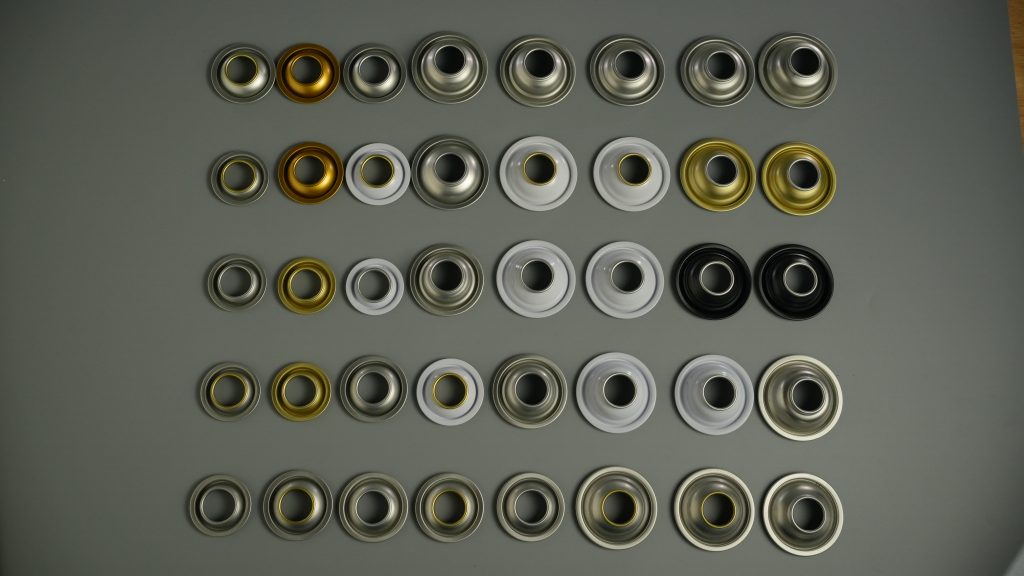

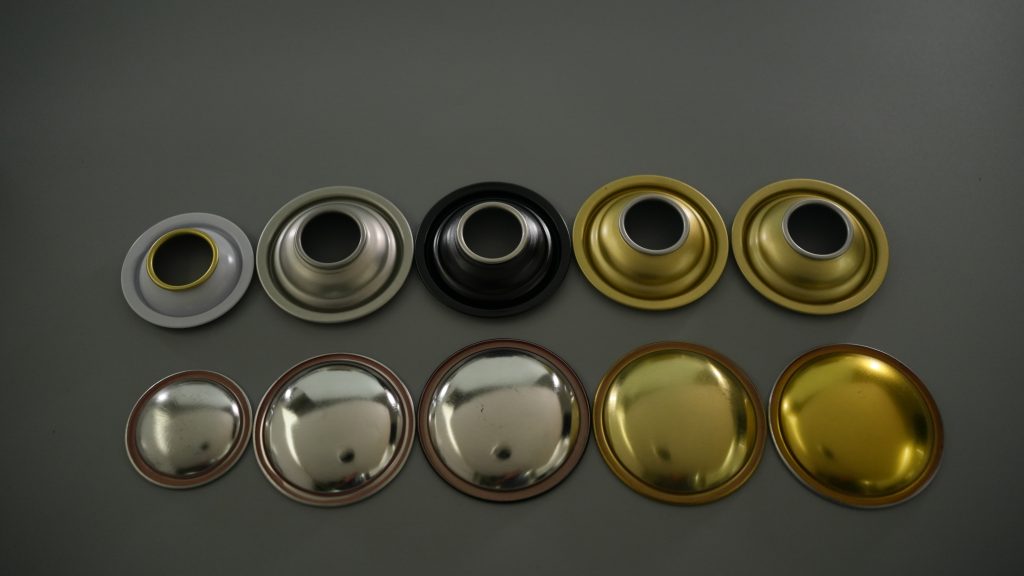

Tinplate’s excellent ductility allows it to be stretched and molded into virtually any shape. Whether you need a classic round can, a sleek square one, a fun spherical can, or a custom-shaped container for branding, tinplate can deliver. It offers incredible design flexibility.

Guardian of the Product

Tinplate’s complete opacity shields light-sensitive formulations, such as certain paints or cosmetics, from degradation. This ensures the product remains stable and effective.

Eco-Warrior

Tinplate is 100% recyclable without losing its inherent properties. Choosing tinplate is a green choice that contributes to a circular economy.

How Do We Ensure Your Tinplate Aerosol Cans are Flawless? Rigorous Quality Control.

Designing a great can is only half the battle. Ensuring every can that leaves our custom tinplate aerosol can factory is reliable requires an unwavering commitment to quality control. Our testing protocols are exhaustive, designed to meet global safety and quality standards.

Here’s a glimpse into our quality assurance lab:

Pressure Integrity Testing: The Strength Test

- Burst Pressure Test: We push cans to their absolute limit to determine the maximum pressure they can withstand before failing. This ensures they can handle extreme conditions during transport or storage without any risk.

- Leak Test: Every can is checked for microscopic leaks in the can body or valve system. This prevents product loss, maintains pressure, and protects the environment.

Spray Performance Assessment: The User Experience Test

- Spray Pattern Analysis: We ensure the spray is uniform, consistent, and perfect for its application, whether it’s a wide mist or a targeted stream.

- Dispensing Rate Measurement: We verify the product is released at the correct flow rate. Too fast, and it’s wasteful; too slow, and it’s frustrating. We strike the perfect balance.

Valve and Actuator Reliability Checks: The “Pssst” Factor

- Actuation Force Test: How much force does it take to spray? We measure this to ensure it’s easy enough for anyone to use but secure enough to prevent accidental discharge.

- Valve Durability Test: We simulate thousands of sprays to confirm the valve continues to function perfectly over its entire lifespan, from the first spray to the last.

Product Stability Evaluation: The Longevity Test

- Shelf-Life Testing: We assess the chemical stability of the product inside the can over time, guaranteeing it remains safe, effective, and performs as expected throughout its advertised shelf life.

A Quick Q&A to Clear the Air

Q: Is the white “aerosol” I see the product?

A: Not exactly! That cloud is often the result of the propellant gas rapidly expanding and condensing moisture in the air. The product itself is dispersed within this cloud as tiny particles for even application.

Q: Are tinplate cans safe?

A: Absolutely. The combination of the tin coating’s corrosion resistance and our rigorous pressure and leak testing ensures they are exceptionally safe for their intended use.

In Conclusion: The Clear Choice for Custom Aerosol Cans

The next time you use an aerosol product, you’ll appreciate the engineering masterpiece in your hand. Tinplate remains the material of choice for a simple reason: it offers an unbeatable combination of strength, safety, formability, and cost-effectiveness.

As a specialist in custom tinplate aerosol cans, we leverage these inherent advantages and back them with a relentless focus on quality control. From pressure testing to spray analysis, we ensure that the cans we create for you are not just containers, but reliable partners for your products.

Ready to explore custom tinplate aerosol solutions that are built to perform? Contact us today to discuss how we can bring your packaging vision to life with reliability and precision.