A Leakage Accident That Sparks Reflection

A cleaning product manufacturer once faced a frustrating issue: a batch of customized water-based aerosol cans worked perfectly during initial testing, but suddenly leaked in bulk after 3 months in the warehouse. Disassembly revealed that the coating at the weld seam had been corroded through by the liquid, exposing the rusty tinplate substrate. This is not an isolated case—As pressure vessels, aerosol cans must withstand both internal propellant pressure and liquid corrosion, making quality control an intricate process.

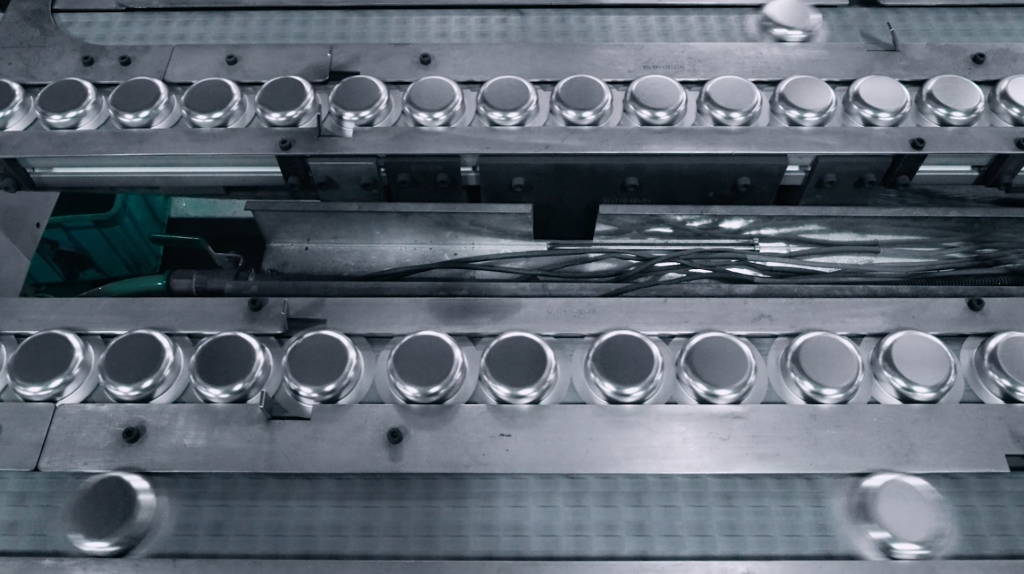

Aerosol products consist of four core components: the can, valve, liquid, and propellant gas. The quality of tinplate aerosol cans directly determines product lifespan and safety. Water-based aerosols, in particular, are highly corrosive and place stringent demands on can quality. Let’s break down the key factors influencing tinplate aerosol can quality, with industry Q&A insights at the end!

1. 6 Core Factors Determining Aerosol Can Quality

The quality of tinplate aerosol cans relies on “inherent material quality + acquired craftsmanship“—any weak link can lead to hazards. Below are key control points summarized from our 10 years of customization experience:

| Impact Dimension | Core Issue | Solution |

|---|---|---|

| Tinplate Substrate | High impurities causing brittleness and pinhole leakage | Use substrates with purity ≥99.5%, prioritizing high-quality domestic materials (China accounted for 36% of global tinplate production in 2022, achieving self-sufficiency) |

| Welding & Recoating | Weld tin layer damage leading to corrosion; cold welding causing leaks | Adopt stable current welding; conduct 120-day compatibility tests between recoating materials and liquids |

| Internal Coating | Bubbles or damage in coatings causing corrosion perforation | Use eco-friendly epoxy-phenolic coatings; ensure dense, undamaged coatings at lid-body joints |

| Seaming Process | Insufficient hook overlap causing micro-leakage | Control seaming hook overlap ≥1.2mm; sample-test seal tightness per batch |

| Leak Detection | Omitted inspections leaving safety hazards | 100% online water bath leak detection; sample-test burst pressure per GB13042-2008 (ordinary cans ≥1.4MPa) |

| Sealant Performance | Solvent swelling causing seal failure | Use low-moisture-transmission silicone sealants; conduct 6-month solvent resistance tests |

In-depth Key Details

- Substrate: The “Inherent Quality” of TinplateMany mistakenly believe “only imported tinplate is high-quality,” but data shows China produced 5.14 million tons of tinplate in 2022, accounting for 36% of the global total, making it the world’s largest producer and exporter. Purity is the real quality determinant—tinplate with excessive impurities has poor ductility, prone to pinholes during manufacturing and subsequent leakage. We conduct flaw detection on every substrate batch to eliminate risks at the source.

- Welding & Recoating: The Most Vulnerable “Line of Defense”Weld seams of three-piece cans are natural weak points: the tin layer is damaged during welding, and if recoating is delayed or incompatible, water-based liquids will corrode the can like “ants eroding a dyke.” A manufacturer once used ordinary paint for recoating to cut costs, resulting in weld perforation by water-based cleaner in just 3 months.

- Leak Detection: The Final Safety GateAerosol cans are flammable and explosive, so leak detection is non-negotiable. We use MFY-07S water bath testers for 100% online inspection—any bubbles after pressurization mean rejection. We also sample-test burst pressure per standards; ordinary cans must withstand over 1.4MPa without breaking.

2. Industry FAQ: Avoid These Pitfalls When Customizing

Q1: Why do water-based aerosols leak more easily?

A: Water-based liquids have high conductivity, accelerating tinplate’s electrochemical reaction. If the internal coating has bubbles or weld recoating is improper, liquids will directly contact the metal substrate, causing corrosion perforation in 3-6 months. Clearly inform us of your liquid’s pH value during customization, and we’ll match a dedicated corrosion-resistant coating.

Q2: Is domestic tinplate inferior to imported?

A: Absolutely not. China exported 1.72 million tons of tinplate in 2022, supplying 5%-7% of the U.S. market. Quality depends on the manufacturer’s standards. Our domestic substrates have 99.8% purity, matching imported performance while reducing customization costs.

Q3: How to judge sealant quality?

A: Focus on solvent resistance and moisture transmission. New low-moisture-transmission silicone sealants (2024) reduce moisture permeability by over 40%, ideal for products stored in high-humidity environments. We conduct 6-month swelling tests with your liquid to ensure sealant effectiveness.

3. 3 Practical Tips for Customizing Tinplate Aerosol Cans

- Clarify core needs: Specify liquid type (water-based/solvent-based), propellant type (DME/propane), and storage conditions—these determine coating and sealant selection.

- Request test reports: Ask for substrate purity, weld tensile strength, and burst pressure reports to avoid “unqualified” products.

- Reserve testing time: Compatibility tests take at least 30 days; combine with production lead time, start customization 2 months in advance.

Closing

Tinplate aerosol can quality is never a “one-time deal”—every step from substrate selection to factory inspection hides critical details. As a customization-focused manufacturer, we adhere to GB13042-2008 standards and integrate latest materials (e.g., low-moisture-transmission sealants, eco-friendly coatings) to ensure each can resists corrosion and pressure. If you’re struggling with water-based aerosol can selection, feel free to consult our customization solutions anytime!