Welcome to Foshan SAILON Tinplate Printing & Can Making Co., Ltd.

News

-

Tinplate VS Aluminum Cans, Why Choose Tinplate for Customization?

Last week, a customer making petpet insect repellent asked: “Both are aerosol cans, why do you recommend tinplate?” The answer actually lies in the raw materials—let’s first look at a 2025 latest material comparison table: Comparison ItemTinplate (Your Company’s Core Material)Traditional AluminumCorrosion ResistanceResists 95% acid-alkali solution, 72h salt spray test no rust (2025 new standard)Resists 60% acid-alkali, 48h salt spray test up to standardCustom FlexibilitySupports 35-100mm diameter, 7-day sample delivery for special-shaped cansOnly regular round shape, 15+ days for special-shaped samplesEnvironmental Recycling Rate95% (meets EU 2025 ESG new regulations)82%Printing Effect8-color UV printing + 3D embossing, no scratches after 500 wearsMax 6-color p...Learn more -

How do enterprises choose the appropriate tinplate can production line?

Our company specializes in custom tinplate aerosol cans. In this highly competitive market, selecting the right can – making production line is extremely crucial. It directly affects production efficiency and product quality, and thus determines our competitiveness in the market. Today, let’s talk about how enterprises should choose a suitable tinplate can – making production line. Clarify Production Capacity Requirements: Calculate Your “Can Volume” Enterprises first need to determine their production capacity based on their own situations. Just like running a restaurant, you have to estimate how many customers you can serve each day to arrange food procurement and the number of chefs. The same goes for making tinplate aerosol cans. Based on sal...Learn more -

Tinplate Aerosol Production Lines: Adaptable Materials, Technological Breakthroughs & Eco-Trends (2025)

1. Why This Cleaner Brand Switched to Tinplate Aerosols? Mr. Li, a procurement manager at a household cleaner company, recently made a key decision: shifting 30% of aluminum can orders to custom tinplate cans. “The EU’s new regulation requires over 80% recyclability by 2026. Tinplate’s 90% recycling rate meets the standard perfectly, plus its production energy consumption is 35% lower than aluminum—saving nearly 150,000 RMB annually.” This choice reflects the upgraded material adaptability of tinplate aerosol production lines. 2. Packaging Material Adaptability: Tinplate as the Eco-Favorite (2025 Data) Material TypeKey FeaturesApplication ScenariosEU 2025 Regulation ComplianceTinplate Can100% recyclable (<2% loss after 10 cycles), low cost, high ba...Learn more -

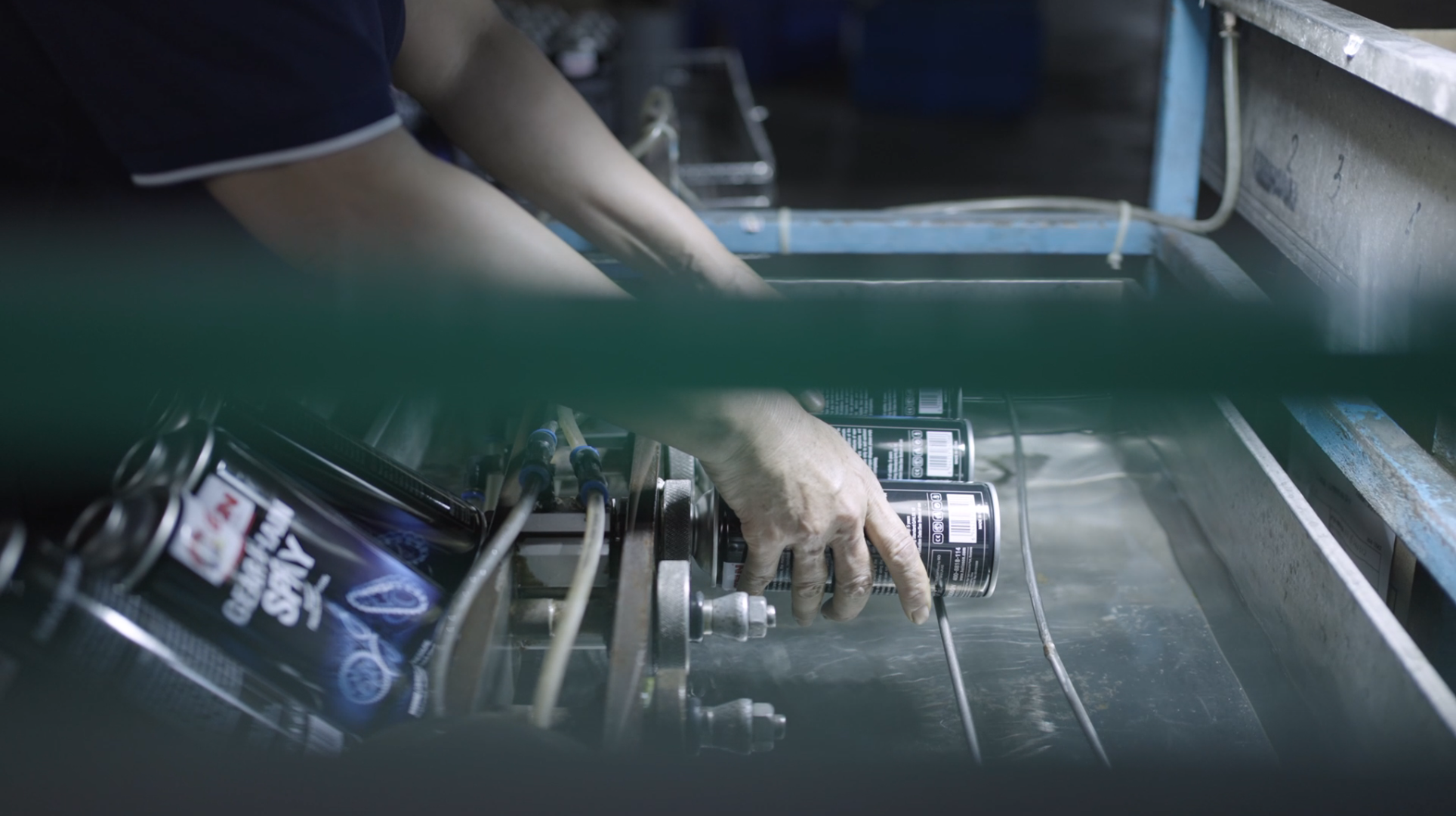

How to Prevent Can Deformation in Tinplate Aerosol Can Production Lines and Ensure Quality

a daily chemical company customizes a batch of tinplate aerosol cans from your company for filling moisturizing sprays. However, during transportation, some of the aerosol cans show obvious dents and deformations, which not only lead to customer returns but also damage the company’s reputation. The root cause of this problem is likely in the quality control link of the production line. As a professional custom tinplate aerosol can enterprise, how to eliminate can deformation from the entire production process has become the key to enhancing product competitiveness rankings. 1. Raw Materials: The “Golden Standard” for Tinplate Selection Tinplate, as the core raw material of aerosol cans, directly determines the anti-deformation ability of the cans. Many cu...Learn more -

Why Seal Integrity Is Non-Negotiable for Custom Tinplate Aerosol Cans

When the production manager of a European skincare brand approached us for 100ml custom tinplate aerosol cans, her first concern was clear: “Last year, 3% of our cans leaked during shipping to Northern Europe, and customer complaints jumped by 15%.” This isn’t an isolated issue—whether for moisturizing sprays, baking release oils, or medical disinfectants, the seal integrity of tinplate aerosol cans defines a brand’s reputation. As a manufacturer specializing in custom tinplate aerosol cans, we frequently field questions about seals from clients. Let’s break down why seal integrity matters, using real-world scenarios. 1. Why do tinplate cans need stricter seal standards than plastic ones? A client once asked, “Plastic cans are lighter—why are tinplate cans held to higher se...Learn more -

Essential for camping! Why custom aerosol cans have become the new favorite of outdoor enthusiasts?

On a freezing winter camping trip in the mountains, a group of outdoor enthusiasts gathered around a portable stove to cook hot pot. Suddenly, someone knocked over a gas canister. A regular aluminum can dented immediately, with gas faintly leaking; but another custom tinplate canister nearby only had a shallow scratch. When screwed back onto the stove, the flame remained steady. This isn’t an accident—it’s the typical performance of custom tinplate butane canisters in outdoor scenarios, and the key reason more campers are ditching regular canisters. Why Custom Tinplate Canisters Are Camping’s “Safety Guardians”? The material properties of tinplate (electro-tinned steel sheets) make it naturally suitable for complex outdoor environments. We once customized a batc...Learn more -

Don’t Just Formulate, Package: How Custom Aerosol Cans Become Your Car Care Brand’s MVP

Let’s be honest. In the crowded auto care aisle, your product has about 3 seconds to make an impression. Before a customer reads your label or knows your price, they see your can. That container isn’t just packaging; it’s your Most Valuable Player (MVP) on the shelf. A custom-designed tinplate aerosol can is the difference between blending in and dominating. It’s the silent salesperson that works 24/7, convincing customers that your product is the premium, professional choice. Why Your “Can” Strategy is as Important as Your Formula A revolutionary formula trapped in a generic can is a missed opportunity. Here’s why investing in custom packaging delivers a massive return: Shelf Impact: A unique shape and vibrant design make your product unm...Learn more -

Unlock the Infinite Possibilities of Spray Paint Art with Custom Tinplate Aerosol Cans

On a weekend afternoon at a city street corner, an artist squats in front of an abandoned wall, busy at work—what he holds in his hand isn’t an ordinary plastic aerosol can, but a custom tinplate aerosol can printed with an exclusive design. When he presses the nozzle, a fine mist of paint adheres evenly to the wall, and in less than half an hour, the outline of a cat leaping off the wall takes shape. Today, spray paint art has long broken free from the label of “niche graffiti” and become a common form of expression in streets, galleries, and even home decor. The core tool that carries this creativity—the aerosol can—has also evolved from a “one-size-fits-all” product to a custom tinplate version that better meets creative needs, giving artists more freedom to create on different ...Learn more -

Tinplate Aerosol Cans: How Aerosol Valves, Actuators, and Caps Enable Efficient Dispensing

1. Daily Scenes: The “Dispensing Code” Behind Tinplate Aerosol Cans When you style your hair in the morning, you press the top of a tinplate hairspray can, and a fine mist sets your strands instantly. When cleaning the kitchen, you press the actuator of a tinplate cleaner can, and foam covers grease precisely—these smooth experiences don’t rely solely on the “can” itself. As a tinplate aerosol can customization manufacturer, we know well that aerosol valves, actuators, and caps are the “invisible cores” determining product dispensing performance. Many clients ask during their first consultation: “Tinplate cans are already high-quality, so why care about valves and accessories?” In fact, the advantages of tinplate aerosol cans—su...Learn more -

In-depth exploration of the design and functions of the conical and dome-shaped spray cans

Aerosol products, from household cleaners to personal care items, have become an integral part of our daily lives. But have you ever wondered about the design behind these products? Among the key components, the aerosol cone and dome play indispensable roles in can design and functionality. This article will take you deep into the intricacies of these parts and how they ensure product efficacy and user convenience. By dissecting the aerosol cone, we can understand the essence of product dispensing and control, while the aerosol dome is critical for can integrity and safety. Join us as we unveil the mysteries of aerosol cones and domes, exploring the fascinating world of can design and function! Why Does Aerosol Can Design Matter?Aerosol cans are not just containers; they are a b...Learn more