Welcome to Foshan SAILON Tinplate Printing & Can Making Co., Ltd.

News

-

Why Are Aerosol Cans Almost Always Made of Tinplate?

You might have wondered why most aerosol cans feel metallic and sturdy. The secret lies in the material they’re made from—tinplate. But what exactly is tinplate? Many people aren’t familiar with this term. In simple terms, tinplate is a thin steel sheet coated with a layer of tin, which is why it’s often referred to as tin-coated steel. This special coating gives the material its unique properties—strength, corrosion resistance, and flexibility. Inside an aerosol can, products like deodorants, paints, or whipped cream are stored under high pressure. These contents are pressurized using gas compressors, forming a fine mist when released. The pressure inside the can is significantly higher than the outside air pressure, which allows the content to be sprayed out as a nano-level ...Learn more -

How to Prevent Can Deformation in Aerosol Can Production Lines?

Aerosol cans, as common pressurized packaging containers, require strict attention to the issue of can deformation during the production process. Can deformation not only affects the product’s visual quality but may also lead to reduced sealing performance and lower pressure resistance, thereby impacting the product’s usability and safety. To prevent can deformation in the production line, it is essential to address multiple aspects, including raw material selection, production process control, equipment maintenance and optimization, as well as quality inspection. Selection and Control of Raw Materials Material Selection Aerosol cans are typically made from metal materials such as tinplate or aluminum. When selecting raw materials, it is crucial to consider the...Learn more -

Safety Protocols for Aerosol Can Production Lines

Aerosol can manufacturing involves multiple hazards such as high-pressure systems, machinery operation, and flammable materials. Therefore, safety management must be integrated throughout the entire production process. Establishing clear guidelines, enhancing protective measures, and implementing strict controls are essential to building a safety-conscious system. This helps ensure personnel safety and equipment reliability while preventing accidents that could lead to financial losses and operational disruptions. Personnel Safety Management People are central to safety management, which involves both awareness and practical operation. All employees must complete systematic safety training before starting work. The training should cover potential risks, operating procedures...Learn more -

Ingredients of Waterproof Leak-Sealing Sprays and Introduction to Filling Equipment

During interior decoration, waterproofing and leak-sealing materials are essential in many areas—all for the sake of convenience and practicality in renovation projects. There is a wide variety of materials available on the market for waterproofing and sealing leaks. But how much do you know about the ingredients of leak-sealing sprays? Let’s take a closer look! Waterproof Leak-Sealing Materials Polymer-Modified CementThis is a type of waterproof material with excellent flexibility. It is primarily produced using polymers as the base material through multiple processes. This material also demonstrates strong water resistance, high temperature tolerance, and long-term durability, making it a reliable choice. Permeability-Resistant GroutThis material is processed from a vari...Learn more -

The Application Prospects of Aerosol Whipped Cream

In recent years, bubble tea has gained remarkable popularity among young consumers, many of whom have developed a strong fascination with this beverage. Dessert shops and tea houses continuously introduce innovative varieties, constantly refreshing people’s understanding of what bubble tea can be. Toppings have played a significant role in this evolution—from milk foam and ice cream to shaken milkshakes, cheese foam, and whipped cream toppings. As cheese foam tea gradually takes a back seat, a new generation of tea beverages led by whipped cream toppings is rising to prominence. Data shows that in 2020, whipped cream-topped drinks accounted for half of all new bubble tea products launched by major brands. Traditionally, preparing whipped cream topping involved a relatively...Learn more -

Knowledge about aerosol cans

When it comes to aerosol products, the aerosol can is an indispensable component. It not only serves as the external packaging but also acts as a reliable barrier against potential leaks. Given its role as a pressure-resistant container, it is also the part most vulnerable to leaks and corrosion. Thus, making the right choice of an aerosol can is a crucial step in the manufacturing process of aerosol products. Diverse Types of Aerosol CansAerosol cans can be primarily classified based on the materials used in their construction. The two most commonly found types in the market are tinplate aerosol cans and aluminum aerosol cans. Tinplate Aerosol CansTinplate cans have gained widespread popularity in the aerosol product industry and are among the most budget-friendly options. ...Learn more -

Production Process of Shaving Foam Aerosol

Shaving cream is a daily chemical product used to assist razors in removing facial hair and unwanted body hair. Traditionally used by men, the market has seen increasing segmentation, with major international cosmetics companies now offering shaving creams specifically designed for women. According to the 2007 edition of China’s Cosmetics Hygiene Standard, shaving cream falls within the scope of cosmetics as it is applied directly to skin areas such as the face. Although electric razors are widely used in households, they often fail to provide a complete shave. Some users may develop skin allergies after about 15 weeks of use, which may be related to exposure to nickel present in razors. When the skin is broken, bacterial infection and excessive friction can increase the abs...Learn more -

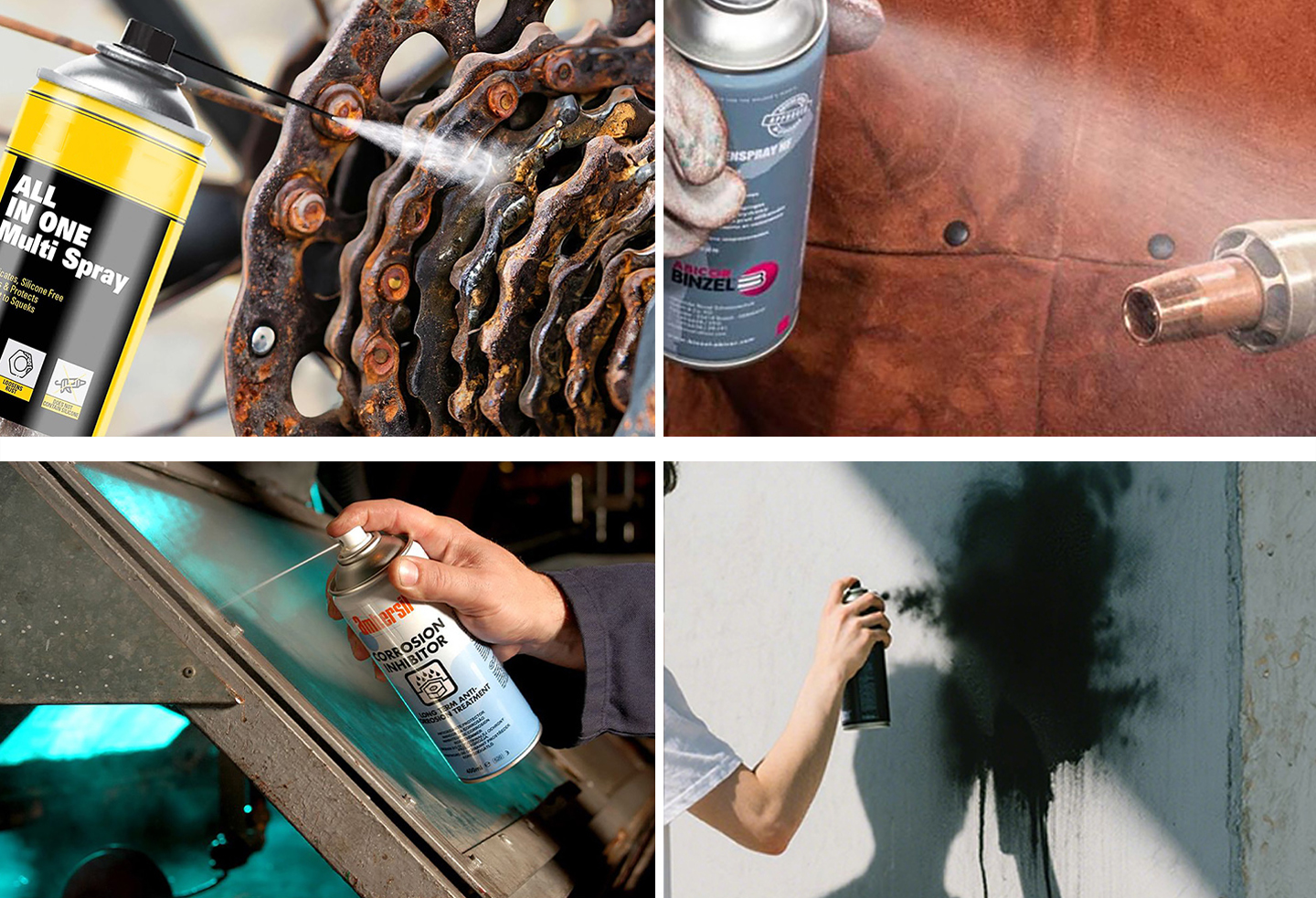

A Guide to Selecting Aerosol Cans

Aerosol cans are a critical component of aerosol products, serving as pressurized containers. Due to their convenience, ease of use, and storage benefits, an increasing number of products are adopting aerosol packaging. These cans are widely used across various industries, including food, industrial manufacturing, daily necessities, cosmetics, pharmaceuticals, and automotive care. When deciding to package a product in aerosol form, several factors regarding the container must be considered. These include the material—whether tinplate or aluminum—the capacity (in milliliters), the type of propellant gas to be filled, and whether the solution may corrode the can. Each of these aspects should be evaluated based on the product’s specific characteristics. Below, we outline key ...Learn more -

Working Principle of Aerosol Can Filling Machines

Aerosol can filling machines represent a specialized category of packaging equipment, typically divided into liquid filling systems and propellant filling (or aerosol charging) systems. Given the pressurized nature of aerosol products, the filling process is distinctly segmented into these two critical stages. The liquid filling unit is responsible for injecting a precise amount of product liquid into the can under standard atmospheric conditions. Subsequently, the aerosol charging unit introduces a metered volume of gas (or liquefied gas) under specific pressure into the same can. A key aspect of this process is that the can must be sealed before the propellant is added to ensure pressure integrity. Therefore, the charging apparatus injects the gas directly through the can’s valve...Learn more -

Characteristics and Filling Process Analysis of Two-Composition Aerosol Packaging

To meet the demand for packaging containers capable of storing high-viscosity formulations and releasing them repeatedly, innovative changes have been made in aerosol product packaging. A notable example is the successful development and widespread adoption of two-composition aerosol systems across various industries. The annual production of such products has reached millions of units and continues to grow. So, what makes two-composition aerosol packaging unique, and how is it filled? Below is a summary of the key features of two-composition aerosol products: Separation of Formulation and Propellant:Since the active formulation and the propellant are stored separately, they do not interact with each other.There is no need to consider compatibility or emulsification betw...Learn more